Resistor Assembly Services for Rail, Transportation & TVM Applications

We provide high-precision Resistor Assembly Services engineered for the demanding electrical, thermal, and mechanical requirements of rail, transportation, and Transit Vehicle Manufacturers (TVM) platforms.

Resistor Assembly Services for Rail, Transportation & MTV Applications

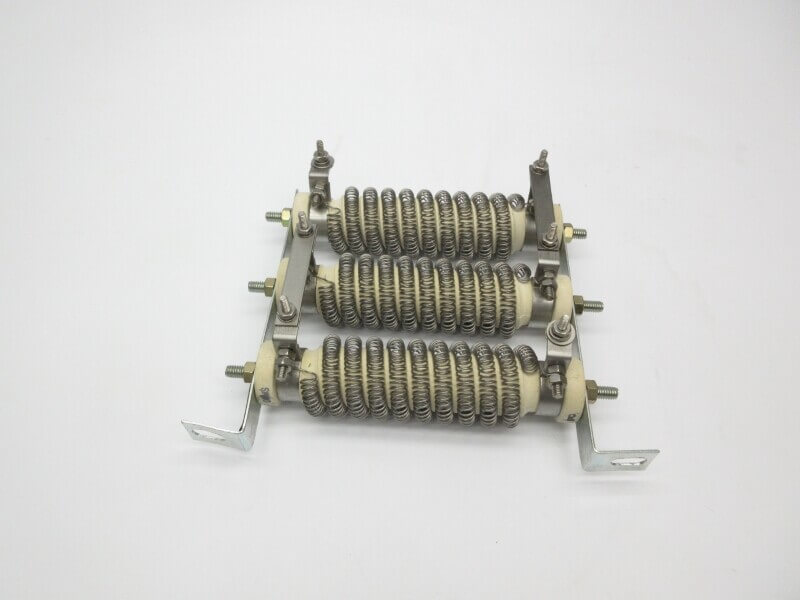

We provide high-precision Resistor Assembly Services engineered for the demanding electrical, thermal, and mechanical requirements of rail, transportation, and mass transit vehicle (MTV) platforms. Our team specializes in producing resistor assemblies that support power control, dynamic braking, load management, propulsion, HVAC, and auxiliary electrical systems across rolling stock and mobility equipment.

Resistor assemblies in transportation environments must deliver stable performance under high currents, sustained heat generation, vibration, and rapid cycling. Our manufacturing processes ensure consistent electrical characteristics, precise resistance values, and mechanical durability—critical for safety-critical subsystems in railcars, locomotives, electric buses, hybrids, and autonomous mobility vehicles.

Our team specializes in producing resistor assemblies that support power control, dynamic braking, load management, propulsion, HVAC, and auxiliary electrical systems across rolling stock and mobility equipment.

Resistor assemblies in transportation environments must deliver stable performance under high currents, sustained heat generation, vibration, and rapid cycling. Our manufacturing processes ensure consistent electrical characteristics, precise resistance values, and mechanical durability—critical for safety-critical subsystems in railcars, locomotives, electric buses, hybrids, and autonomous mobility vehicles.

Comprehensive Resistor Assembly Capabilities

We assemble resistor units used across a wide range of transportation electrical systems, including:

Comprehensive Resistor Assembly Capabilities

- Dynamic Braking Resistors – high-current, high-heat assemblies for electric and hybrid propulsion systems.

- Power Resistor Modules – load banks, current-limiting resistors, and voltage-dropping units.

- Heating & Thermal Resistors – resistive heating elements for HVAC and climate control systems.

- Control & Auxiliary Resistors – start/soft-charge resistors, snubber resistors, relay resistors, and protective circuitry.

- Custom Resistor Banks – multi-stage resistor ladders, variable resistance assemblies, and integrated thermal protection designs.

Precision Manufacturing & Thermal Management Expertise

Our technicians integrate electrical components, mechanical housings, and thermal management features into fully validated assemblies. Capabilities include:

- Precision mounting, fastening, torquing, and enclosure integration

- High-temperature wiring, terminals, and connectorization

- Ceramic, stainless steel, aluminum, and heat-sink structural integration

- Airflow, ventilation, and thermal dissipation optimization

- Insulation, spacing, and clearance control for high-current systems

Each assembly is built with close attention to thermal load, electrical stability, and long-term durability under continuous cycling.

Testing & Quality Validation

Every resistor assembly undergoes rigorous testing, including:

- Resistance value measurement and tolerance verification

- High-temperature and load-cycle testing

- Dielectric and insulation resistance checks

- Vibration and mechanical integrity inspection

- Full functional validation for integrated assemblies

All production follows ISO-aligned quality procedures and industry standards for safety and electrical performance.

Built for Transportation Reliability

Our resistor assemblies are engineered to perform in the harshest rail and mobility environments—supporting dependable operation of propulsion, braking, HVAC, and control systems throughout the full lifecycle of the vehicle.